If you’ve ever changed your own oil, bought tools, checked tire pressure, or looked at engine specs, you’ve seen the letters SAE. They show up on oil bottles, socket sets, torque charts, and even vehicle standards — usually without explanation.

Picture a typical modern car: a turbocharged four-cylinder engine, aluminum block, precise tolerances, sensors everywhere. None of that works safely or consistently without agreed-upon rules for measurements, materials, testing, and performance.

That’s where SAE comes in. In this article, I’ll explain what SAE stands for, where it came from, how it quietly shapes the cars we drive, the tools we use, and the numbers we trust — and why understanding it helps you make better decisions as a car owner or enthusiast.

This isn’t a dictionary definition. It’s a real-world explanation, for everyone who wants clarity, not jargon.

Short note on information sources

This article was written using authoritative, high-reputation technical sources, including official publications and educational materials from SAE International, long-standing automotive engineering references, and widely cited industry documentation used by manufacturers and professional technicians.

These sources ensure accuracy, consistency, and real-world relevance rather than opinion or speculation.

The simple answer first

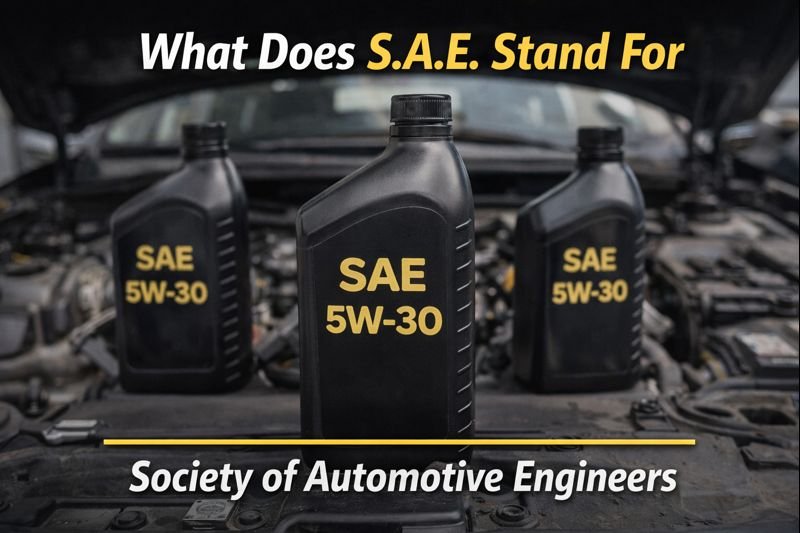

S.A.E. stands for Society of Automotive Engineers.

Today, the organization is officially known as SAE International, but the abbreviation “SAE” is still widely used in automotive, aerospace, and mechanical fields.

At its core, SAE is a professional organization that creates standards, testing methods, technical papers, and educational resources for vehicles, engines, fuels, lubricants, tools, and related technologies.

If a spec, number, or measurement in the automotive world feels consistent and trustworthy, there’s a good chance SAE had something to do with it.

Why SAE exists at all (the historical context)

In the early days of automobiles, there were no shared rules. One manufacturer measured horsepower one way, another measured it differently. Bolt sizes varied wildly. Materials were inconsistent. Even basic terminology changed from company to company.

In 1905, a group of engineers recognized a problem: innovation without standardization leads to chaos. They formed what became the Society of Automotive Engineers to bring order, consistency, and credibility to a rapidly growing industry.

The goal was never to control manufacturers — it was to make sure engineers, mechanics, suppliers, and consumers were all speaking the same technical language.

That mission still holds today, more than a century later.

What SAE actually does (beyond the name)

SAE is not a government body, and it doesn’t build cars. Its influence comes from voluntary technical authority. Manufacturers follow SAE standards because they work, not because they’re forced to.

Here’s what SAE does in practical terms:

- Develops technical standards

- Defines measurement methods

- Publishes engineering research papers

- Establishes testing procedures

- Creates education and certification programs

These standards are used worldwide — not just in the United States.

SAE in everyday car ownership (where you’ve already seen it)

Even if you’ve never heard the full name before, you’ve interacted with SAE countless times.

1. Motor oil ratings (SAE viscosity grades)

When you see oil labeled SAE 5W-30 or SAE 0W-20, that viscosity classification comes from SAE testing standards.

- The first number (before the W) relates to cold-temperature flow

- The second number relates to thickness at operating temperature

SAE doesn’t make the oil — it defines how viscosity is measured, ensuring that 5W-30 means the same thing across brands.

Without SAE, oil labels would be marketing guesses instead of engineering facts.

2. Tool sizes (SAE vs metric)

When people say “SAE tools,” they usually mean inch-based fasteners, as opposed to metric (millimeter-based).

Examples:

- SAE: 1/2″, 9/16″, 3/4″

- Metric: 10mm, 13mm, 19mm

These sizing systems exist because SAE historically standardized inch-based measurements for American manufacturing, while metric standards evolved elsewhere.

Even today, many older American vehicles still use SAE fasteners, while modern vehicles blend both.

3. Horsepower and torque measurements

Horsepower numbers are only meaningful if measured consistently. SAE defines how engines are tested, including:

- Temperature conditions

- Accessories attached (alternator, water pump, etc.)

- Correction factors

That’s why you’ll sometimes see “SAE net horsepower” in specifications. It means the engine was tested using a standardized, realistic method — not an inflated lab number.

SAE vs other standards (why it matters)

SAE isn’t the only standards organization in the world. Others include ISO, DIN, and ASTM. So why does SAE matter specifically in automotive contexts?

Because SAE standards are written by engineers who work directly in vehicle design, testing, and manufacturing.

That gives SAE documents a practical, application-first approach.

For example:

- ISO may define a global framework

- SAE defines how that framework works inside an engine bay

That’s why many automakers reference both ISO and SAE in technical documentation.

SAE standards you’ve probably never noticed (but rely on)

Fuel testing and classification

SAE defines test methods for fuel volatility, knock resistance, and emissions behavior.

Brake performance testing

Stopping distance, fade resistance, and heat tolerance are evaluated using SAE procedures.

Fastener strength grades

Bolt markings and tensile strength ratings follow SAE material standards.

Electrical connectors

Many automotive connectors and wiring practices follow SAE durability and safety specs.

You don’t see the logo — but you benefit from the results.

SAE and modern vehicles (it’s not old-school)

Some people think SAE only applies to old carbureted engines or American muscle cars. That’s outdated thinking.

SAE standards now cover:

- Hybrid and electric vehicles

- Battery safety and testing

- Autonomous driving systems

- Advanced driver-assistance systems (ADAS)

- Hydrogen fuel systems

The organization evolved as vehicles evolved.

Why manufacturers follow SAE voluntarily

Automakers aren’t legally required to use SAE standards — so why do they?

Because:

- Engineers trust them

- Suppliers are aligned with them

- Testing becomes repeatable

- Liability risk is reduced

- Global collaboration is easier

A shared standard saves time, money, and mistakes.

Common misconceptions about SAE

“SAE only means tool size”

That’s just one small part of what SAE represents.

“SAE is outdated”

SAE publishes thousands of new and revised documents every year.

“SAE is only American”

Despite its roots, SAE International works globally with engineers from dozens of countries.

SAE vs Metric: not a rivalry, a system choice

The SAE and metric systems coexist because they serve different historical and industrial needs.

- Metric excels in scientific uniformity

- SAE excels in legacy compatibility and tooling

Modern cars often combine both — metric fasteners with SAE-defined testing methods.

Understanding this helps explain why your 10mm socket disappears while your 1/2″ wrench still fits something else perfectly.

How SAE impacts repair shops and technicians

Professional mechanics rely on SAE standards daily, even if they don’t say it out loud.

- Torque specs come from SAE testing

- Oil recommendations rely on SAE viscosity grades

- Diagnostic procedures reference SAE definitions

A good technician trusts numbers only when they come from a recognized standard — and SAE is one of the most trusted.

SAE in education and motorsports

SAE also runs:

- Student engineering competitions

- Formula SAE and Baja SAE programs

- Professional certifications

Many engineers working at major automakers today started in SAE student programs, building and racing vehicles under real engineering constraints.

Why you should care as a car owner

Understanding SAE helps you:

- Buy the correct oil confidently

- Understand horsepower claims realistically

- Choose proper tools

- Avoid misinformation

- Communicate better with mechanics

It turns guesswork into informed decisions.

A practical example: oil confusion solved

If a mechanic says your car needs SAE 0W-20, that’s not a suggestion — it’s a specification based on engine design, bearing clearances, and operating temperature.

Ignoring SAE guidance here can:

- Reduce lubrication

- Increase wear

- Void warranties

This is where standards directly protect your engine.

Final thoughts

SAE isn’t just an acronym — it’s the quiet backbone of automotive consistency. From the oil you pour into your engine to the horsepower numbers you compare online, SAE standards make sure those details mean something real.

Understanding what SAE stands for doesn’t require an engineering degree, but it does give you an edge: clarity in a world full of automotive noise.