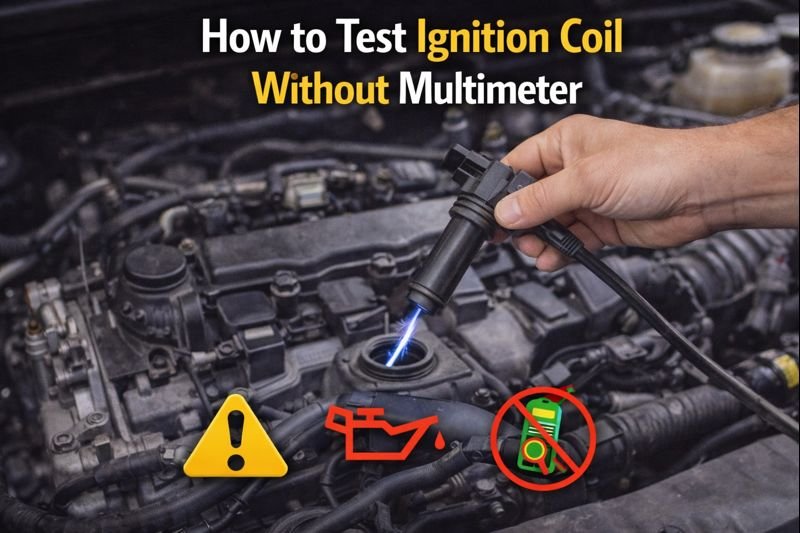

The ignition coil is one of those engine parts most drivers never think about until something feels off. A rough idle, sudden misfires, hesitation during acceleration, or a check engine light can all point toward ignition trouble.

While professional testing tools make diagnosis easier, many people find themselves without a multimeter when a problem starts. That does not mean useful checks are impossible. Modern ignition systems are designed with predictable behavior, and failing coils often leave behind clear clues.

By paying attention to engine response, listening carefully, and performing a few safe hands-on checks, it is possible to narrow down whether an ignition coil is the likely cause.

These methods do not replace professional diagnostics, but they can help decide whether a coil deserves further attention before spending money on parts or labor. A careful, step-by-step approach keeps the process safe, practical, and surprisingly effective.

What An Ignition Coil Does And Why It Fails

The Role Of The Ignition Coil

An ignition coil converts low-voltage power from the battery into high-voltage electricity needed to fire the spark plugs. Each spark plug relies on a strong, consistent spark to ignite the air-fuel mixture inside the engine.

Weak spark equals poor combustion.

Coil-On-Plug Versus Pack Systems

Many modern vehicles use coil-on-plug systems, where each cylinder has its own coil mounted directly over the spark plug. Older designs may use coil packs that serve multiple cylinders.

Testing approach depends on design.

Common Reasons Ignition Coils Go Bad

Heat is the biggest enemy of ignition coils. Over time, internal windings break down, insulation cracks, and electrical resistance changes. Oil leaks, moisture intrusion, and vibration also shorten coil life.

Failure often develops gradually.

Early Warning Signs

Small misfires, reduced fuel efficiency, sluggish throttle response, or occasional stalling can all point toward a weakening coil.

Symptoms often worsen under load.

Safety Precautions Before Testing

Avoiding Electrical Shock

Ignition systems produce very high voltage. Never touch coil terminals or spark plug connectors while the engine is running.

High voltage can cause serious injury.

Working With A Cool Engine

Allow the engine to cool before touching coils. Hot components increase burn risk and make handling uncomfortable.

Heat also masks cracks.

Disconnecting The Battery When Needed

For inspections involving unplugging connectors, disconnecting the battery prevents accidental shorts.

Safety comes first.

Wearing Protective Gear

Gloves and eye protection reduce risk from debris, sparks, or sudden movement.

Preparation prevents accidents.

Visual And Physical Inspection Methods

Checking For Cracks And Damage

Remove the ignition coil and inspect the housing closely. Cracks, burn marks, melted plastic, or swelling indicate failure.

Physical damage rarely lies.

Inspecting Electrical Connectors

Loose, corroded, or oil-soaked connectors interfere with power delivery. Bent pins or broken clips can mimic coil failure.

Connection issues cause misfires.

Looking For Oil Or Moisture Contamination

Oil leaking from valve cover gaskets often fills spark plug wells, damaging coils. Moisture intrusion causes corrosion and short circuits.

Contamination accelerates failure.

Examining The Spark Plug Boot

The rubber boot should be flexible and intact. Hard, brittle, or cracked boots allow voltage to escape before reaching the spark plug.

Boot condition affects spark strength.

Engine Behavior Tests Without Tools

Cylinder Drop Test

Start the engine and let it idle. One at a time, unplug each ignition coil connector briefly, then reconnect it. Listen for changes in engine behavior.

A healthy cylinder causes noticeable roughness when disconnected.

If unplugging a coil makes little or no difference, that coil or cylinder is already weak.

Idle Quality Observation

A failing ignition coil often causes uneven idle. The engine may shake, stumble, or sound inconsistent.

Smooth idle suggests stronger ignition.

Acceleration Response Check

During gentle acceleration, misfiring coils cause hesitation or jerking. Hard acceleration may worsen the problem.

Load reveals weakness.

Cold Start Versus Warm Engine Behavior

Some coils fail only when hot. If the engine runs smoothly when cold but misfires after warming up, heat-related coil failure is possible.

Temperature sensitivity matters.

Swap Testing For Coil-On-Plug Systems

Identifying The Suspect Cylinder

Use engine behavior or trouble codes if available to identify the cylinder that appears to misfire.

Observation narrows focus.

Swapping Coils Between Cylinders

Remove the suspected coil and swap it with a coil from another cylinder. Start the engine and observe behavior.

If the misfire moves with the coil, the coil is likely faulty.

Watching For Symptom Movement

A misfire that follows the coil confirms coil failure. A misfire that stays in the same cylinder points to spark plugs, wiring, or injector issues.

Movement provides clarity.

Benefits Of Swap Testing

This method requires no tools and offers strong confirmation in coil-on-plug systems.

Simple but effective.

Spark Plug Inspection As An Indirect Test

Removing And Inspecting Spark Plugs

A failing coil often leaves spark plugs fouled or unevenly colored. Compare the suspect cylinder plug to others.

Differences reveal patterns.

Signs Of Weak Spark

Wet fuel, carbon buildup, or oil residue on one plug suggests incomplete combustion.

Weak ignition leaves traces.

Comparing Gap And Wear

Excessive gap or worn electrodes stress ignition coils and can accelerate failure.

Plug condition influences coil health.

Replacing Plugs Before Condemning Coils

Worn spark plugs can mimic coil failure. Installing new plugs may resolve misfires without replacing coils.

Start with basics.

Listening And Smell-Based Clues

Popping Or Snapping Sounds

Arcing coils may produce faint snapping or popping noises, especially in low light.

Escaping voltage creates sound.

Burning Smell Near Coils

A burnt plastic or electrical smell near the valve cover may indicate coil overheating.

Odor often precedes failure.

Misfire Sounds From Exhaust

Backfiring or popping from the exhaust under load suggests ignition timing or spark issues.

Combustion irregularities become audible.

Check Engine Light And Driveability Clues

Flashing Versus Solid Warning Lights

A flashing warning light usually indicates active misfires that can damage the catalytic converter.

Immediate attention is required.

Reduced Power Modes

Some vehicles limit power when misfires are detected. This protects the engine but reduces performance.

Protection mode hints at ignition problems.

Fuel Smell Or Poor Mileage

Unburned fuel from misfires reduces efficiency and creates noticeable odor.

Ignition quality affects consumption.

When These Methods Are Enough And When They Are Not

Situations Where No-Tool Testing Works Well

Clear misfires, coil-on-plug systems, and consistent symptoms respond well to swap tests and inspections.

Patterns simplify diagnosis.

Situations Requiring Professional Tools

Intermittent failures, multiple misfires, or modern direct injection systems may require advanced testing.

Complex systems demand precision.

Avoiding Unnecessary Part Replacement

Replacing coils blindly can be expensive. Simple checks reduce guesswork.

Diagnosis saves money.

Preventing Ignition Coil Problems

Addressing Oil Leaks Early

Fixing valve cover gasket leaks protects coils from oil contamination.

Prevention extends lifespan.

Replacing Spark Plugs On Schedule

Worn plugs increase coil workload. Fresh plugs reduce stress on ignition components.

Maintenance supports reliability.

Avoiding Water Exposure

Pressure washing engines or driving through deep water increases moisture intrusion risk.

Dry conditions protect electronics.

Using Quality Replacement Parts

Low-quality coils fail sooner. Trusted brands last longer and perform more consistently.

Quality matters.

Common Myths About Ignition Coil Testing

Some believe coils either work or fail completely. In reality, many coils weaken gradually. Others assume misfires always trigger warning lights, which is not always true.

Symptoms vary by vehicle.

A multimeter is helpful but not mandatory for initial evaluation.

Observation remains valuable.

Repair And Replacement Considerations

Replacing One Coil Or Multiple Coils

If one coil fails, others may follow due to age and heat exposure. Some owners replace coils in pairs or sets.

Strategy depends on budget.

Labor And Accessibility

Coil replacement is often simple and quick. Accessibility varies by engine design.

Ease influences cost.

Resetting Warning Lights

Some vehicles require clearing codes after coil replacement.

Lights may persist without reset.

Final Thoughts

Testing an ignition coil without a multimeter is possible through careful observation, simple swap testing, and basic inspection. Engine behavior, sound, smell, and physical condition provide valuable clues when evaluated together. While these methods do not replace professional diagnostics, they offer a reliable way to identify likely coil issues and decide on next steps with confidence.

Addressing ignition problems early protects engine performance, fuel efficiency, and emissions components. A thoughtful approach reduces unnecessary repairs and helps ensure smooth operation. With patience and attention to detail, even basic checks can reveal a great deal about ignition system health.