Every internal combustion engine depends on one basic principle to operate correctly: the ability to compress air and fuel inside the cylinders. This compression creates the force needed for combustion, power, and smooth operation.

When compression drops below normal levels, the engine begins to struggle in ways that are often confusing and frustrating for drivers. Performance issues may appear slowly, sometimes disguised as fuel problems, ignition faults, or sensor failures.

Low engine compression does not usually happen overnight. It develops gradually as internal components wear, seals weaken, or damage occurs inside the engine.

Because the symptoms overlap with many other mechanical issues, compression problems are frequently misdiagnosed or ignored until they become severe. Knowing how low compression affects engine behavior makes it easier to recognize early warning signs and avoid costly repairs.

A closer look at the symptoms, causes, and consequences of low engine compression reveals why this condition has such a powerful impact on reliability and performance.

What Engine Compression Means And Why It Matters

How Compression Supports Combustion

Compression squeezes the air and fuel mixture inside the cylinder before ignition. This process increases temperature and pressure, allowing the mixture to burn efficiently and produce power. Proper compression ensures strong combustion and consistent engine output.

When compression is low, combustion becomes weak or incomplete.

Relationship Between Compression And Power

Each cylinder contributes power during the combustion cycle. If compression drops in one or more cylinders, overall engine output decreases. The engine may still run, but it cannot perform as designed.

Power loss becomes more noticeable as compression imbalance increases.

Sealing Inside The Engine

Compression relies on tight seals created by piston rings, valves, and head gaskets. These components must prevent air from escaping during the compression stroke.

Any loss of sealing directly reduces compression pressure.

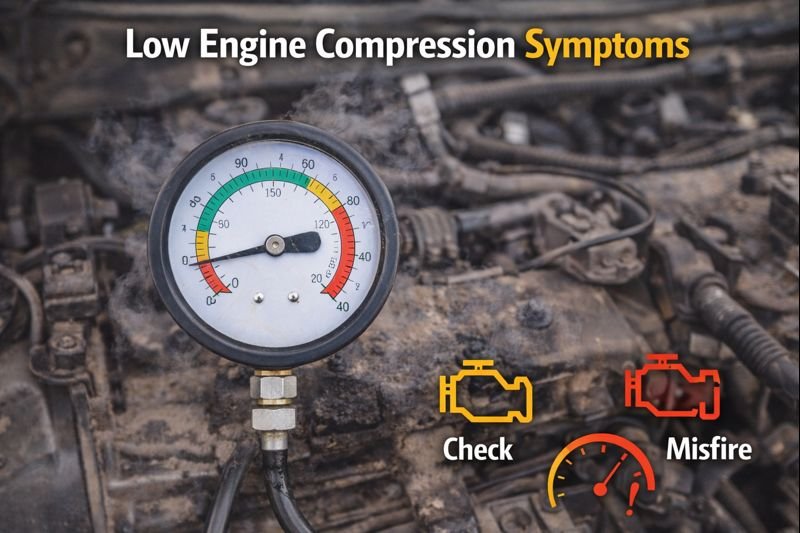

Common Low Engine Compression Symptoms

Hard Starting Or No Start Condition

Low compression makes it difficult for the engine to build enough pressure to ignite the air-fuel mixture. Cold starts become especially challenging.

In severe cases, the engine may crank normally but fail to start at all.

Noticeable Loss Of Power

One of the most common symptoms is reduced acceleration. The engine may feel weak, sluggish, or unresponsive when pressing the accelerator.

Climbing hills or carrying loads becomes more difficult.

Rough Idle And Engine Vibration

Engines with low compression often idle unevenly. Misfiring cylinders cause shaking, vibration, or unstable idle speed.

The engine may sound uneven or struggle to maintain steady operation.

Misfires Under Load

Low compression prevents consistent combustion. This leads to misfires, especially during acceleration or under load.

Misfires may trigger warning lights and fault codes.

Increased Fuel Consumption

When combustion efficiency drops, the engine uses more fuel to maintain power. Fuel economy often declines without obvious changes in driving habits.

Poor compression reduces efficiency.

Excessive Exhaust Smoke

Incomplete combustion caused by low compression can result in visible exhaust smoke. Blue smoke often indicates oil entering the combustion chamber, while white or gray smoke may suggest other internal issues.

Smoke color provides clues to internal damage.

How Low Compression Changes Engine Behavior Over Time

Gradual Performance Decline

Low compression usually worsens gradually. Drivers may adapt to reduced power without realizing something is wrong.

This slow decline delays diagnosis.

Engine Noise Changes

Tapping, knocking, or unusual mechanical sounds may appear as components wear further. Valve train noise is common when compression-related wear progresses.

Unusual sounds often indicate internal stress.

Unstable Idle When Warm

Some engines idle acceptably when cold but run poorly once warm. Heat expands worn components, worsening compression loss.

Temperature sensitivity often points to internal sealing problems.

Common Causes Of Low Engine Compression

Worn Piston Rings

Piston rings seal the gap between the piston and cylinder wall. Over time, they wear or become stuck due to carbon buildup.

Worn rings allow air and combustion gases to escape into the crankcase.

Damaged Or Burnt Valves

Valves must seal tightly against their seats. Burnt, bent, or worn valves leak air during compression.

Valve damage often affects one cylinder more than others.

Blown Head Gasket

A failed head gasket allows compression to escape between cylinders or into the cooling system. This often causes overheating and coolant loss.

Head gasket failure usually produces multiple symptoms at once.

Cylinder Wall Damage

Scratches, scoring, or excessive wear on cylinder walls prevent proper sealing. This damage reduces compression even with healthy piston rings.

Severe wear often requires engine rebuilding.

Timing Issues

Incorrect valve timing prevents valves from closing properly during compression. Timing chain or belt problems can cause widespread compression loss.

Timing-related compression loss often affects multiple cylinders.

Symptoms Based On Single Versus Multiple Cylinders

Single Cylinder Compression Loss

When only one cylinder has low compression, the engine may still run but feel rough. Misfires are localized, and power loss is moderate.

Fault codes often point to a specific cylinder.

Multiple Cylinder Compression Loss

Low compression across multiple cylinders causes severe power loss, rough running, and starting problems.

This condition often signals major internal damage.

Uneven Compression Across Cylinders

Engines rely on balanced compression. Uneven readings cause vibration and inconsistent power delivery.

Balance matters as much as absolute pressure.

How Low Compression Affects Modern Engines

Impact On Fuel Injection Systems

Modern fuel injection relies on precise airflow and combustion feedback. Low compression disrupts this balance.

The engine control system may struggle to compensate.

Variable Valve Timing Problems

Engines with variable valve timing depend on oil pressure and precise mechanical operation. Low compression often accompanies oil contamination and wear.

Timing system faults may appear alongside compression issues.

Turbocharged Engine Sensitivity

Turbocharged engines amplify the effects of low compression. Boost pressure escapes through worn seals, reducing performance significantly.

Turbo systems cannot compensate for poor compression.

Warning Signs Often Mistaken For Other Problems

Confusion With Ignition Issues

Misfires caused by low compression are often blamed on spark plugs or coils. Replacing ignition components does not resolve the root problem.

Repeated ignition failures suggest deeper issues.

Fuel System Misdiagnosis

Loss of power and rough running are frequently attributed to fuel injectors or pumps. While fuel issues exist, compression problems persist regardless of fuel quality.

Compression testing clarifies the cause.

Sensor Replacement Without Results

Modern engines may trigger sensor-related fault codes when combustion becomes unstable. Replacing sensors rarely fixes compression loss.

Codes point to symptoms, not always causes.

How Low Compression Is Diagnosed

Compression Testing

A compression test measures pressure in each cylinder during cranking. Low readings indicate sealing problems.

Comparing cylinders reveals imbalance.

Leak-Down Testing

Leak-down tests identify where compression escapes. Air is introduced into the cylinder, and leakage paths are observed.

This method pinpoints worn rings, valves, or gaskets.

Visual Inspection And Supporting Tests

Oil condition, exhaust smoke, and cooling system behavior support compression test findings.

Diagnosis relies on patterns, not a single test.

Can You Drive With Low Engine Compression

Short-Term Driving Risks

Some vehicles with mild compression loss remain drivable for a short time. However, performance and efficiency suffer.

Driving continues to accelerate wear.

Long-Term Consequences

Continued operation worsens internal damage. What starts as a single-cylinder issue can spread.

Repair costs increase significantly over time.

Safety Considerations

Loss of power during merging or passing can create dangerous situations.

Predictability matters for safe driving.

Repair Options And Cost Considerations

Minor Repairs

Valve adjustments, carbon cleaning, or replacing seals may restore compression in mild cases.

Early diagnosis allows simpler repairs.

Major Engine Repairs

Worn rings, damaged cylinders, or blown head gaskets require extensive labor. Engine rebuilding or replacement may be necessary.

Costs rise quickly once internal damage is severe.

Economic Evaluation

Vehicle age, mileage, and overall condition influence repair decisions. Sometimes replacement is more practical.

Careful evaluation prevents wasted expense.

Preventing Compression Loss

Regular Oil Changes

Clean oil protects piston rings and valve components. Sludge accelerates wear.

Maintenance preserves sealing surfaces.

Avoiding Overheating

Overheating warps engine components and damages gaskets. Cooling system health directly affects compression longevity.

Temperature control matters.

Addressing Problems Early

Ignoring misfires, oil consumption, or overheating allows damage to progress.

Early attention saves engines.

Common Myths About Low Compression

Some believe low compression always means engine replacement. In reality, early-stage problems may be repairable.

Another myth is that additives can restore compression permanently. Temporary improvements do not fix mechanical wear.

Real solutions address physical causes.

Final Thoughts

Low engine compression affects how an engine starts, runs, and performs at every level. Symptoms such as hard starting, power loss, rough idle, misfires, and increased fuel consumption all trace back to one core issue: the engine’s inability to seal and compress air properly. Because compression loss develops gradually, it often goes unnoticed until damage becomes advanced.

Recognizing early symptoms allows timely diagnosis and prevents minor wear from turning into major failure. Compression health depends on proper lubrication, temperature control, and regular maintenance. Treating warning signs seriously preserves engine performance, reliability, and long-term value.