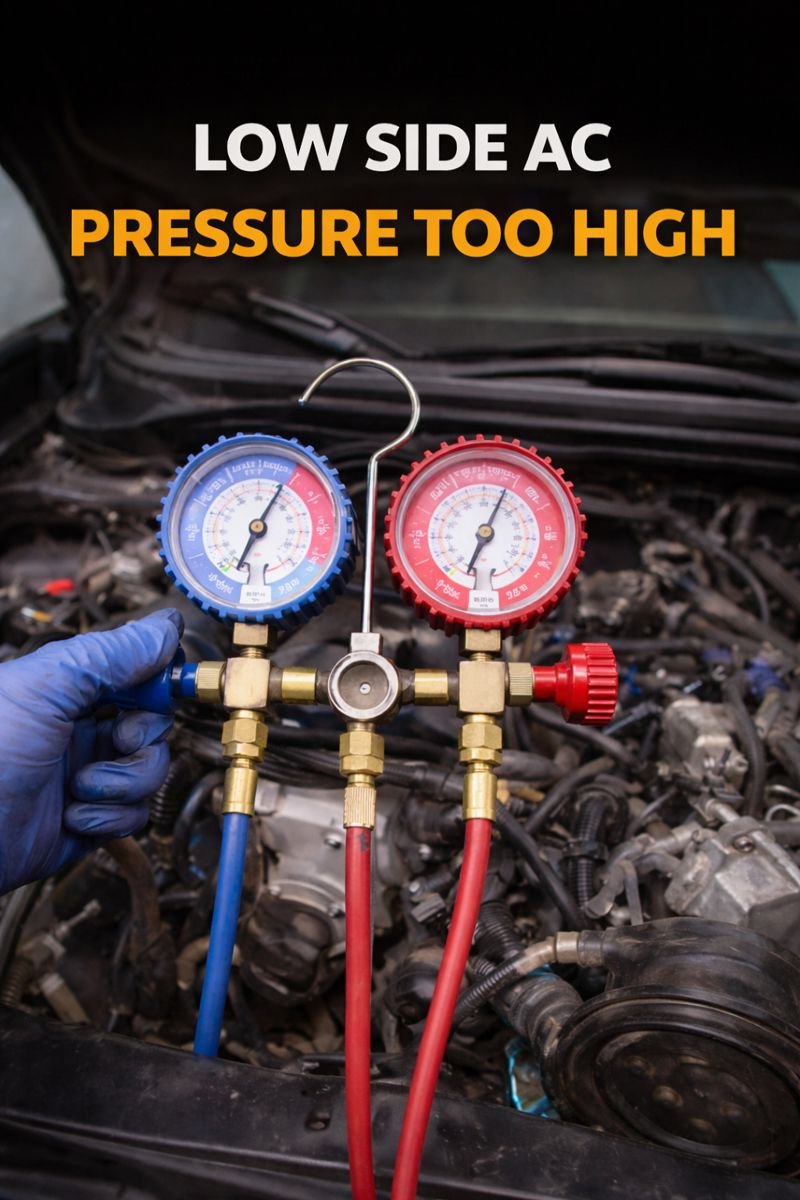

An automotive air conditioning system is built around balance. Pressure, temperature, airflow, and refrigerant movement must stay within a narrow range for cold air to reach the cabin. When something goes wrong, gauge readings often provide the first clue.

One of the most confusing readings for both car owners and technicians is low side AC pressure that is too high. On the surface, it feels backward. If cooling is weak, many people expect pressure to be low.

Instead, the low side gauge shows higher-than-normal numbers, sometimes well above expected operating range.

This condition often leads to incorrect repairs, unnecessary refrigerant charging, or compressor replacement that does not solve the issue. High low-side pressure does not point to a single failure.

It is a symptom created by airflow problems, refrigerant imbalance, mechanical faults, or control issues. Here you will know about what low side pressure actually represents, why it can rise beyond normal levels, how to interpret gauge readings correctly, and which fixes address the real cause rather than masking the problem.

What Low Side AC Pressure Represents

The low side of an AC system is the suction side of the compressor. It reflects how effectively the system is absorbing heat from the cabin.

When operating correctly, low side pressure:

- Drops as refrigerant absorbs heat in the evaporator

- Stays within a stable range based on ambient temperature

- Allows refrigerant to boil at a low temperature

Low side pressure is directly tied to cooling performance. When it runs too high, refrigerant is not expanding or absorbing heat properly.

Normal Low Side Pressure Range

Low side pressure varies by vehicle and refrigerant type, but most systems using modern refrigerants fall within a general window.

Under typical conditions:

- Low side pressure often sits between 25 and 45 psi

- Hot weather may push it slightly higher

- Stable cooling keeps it consistent

Readings far above this range usually indicate a system imbalance rather than normal operation.

Why High Low Side Pressure Is A Problem

High low side pressure means refrigerant is not dropping in pressure enough before entering the evaporator.

When pressure stays high:

- Refrigerant does not boil efficiently

- Heat absorption is reduced

- Air from the vents feels warm or mildly cool

- Compressor load may increase

Cooling performance drops even though pressures appear strong.

Overcharged AC System And High Low Side Pressure

One of the most common causes of high low side pressure is overcharging.

Too much refrigerant overwhelms the system. Instead of expanding properly, refrigerant remains in a semi-liquid state in areas where it should be vapor.

This causes:

- Elevated pressure on both low and high sides

- Reduced temperature drop across the evaporator

- Weak cooling despite full system charge

Overcharging often happens when refrigerant is added based on pressure alone instead of weight.

Why Adding Refrigerant Often Makes It Worse

Many people add refrigerant when cooling feels weak, assuming the system is low.

If the real issue is airflow or restriction, adding refrigerant raises low side pressure even further.

This reduces cooling efficiency and can stress the compressor.

Proper charging always requires evacuation and measured refill, not topping off blindly.

Poor Airflow Across The Evaporator

The evaporator relies on airflow to remove heat from the cabin.

When airflow is restricted:

- Refrigerant absorbs less heat

- Pressure remains high

- Cooling output drops

Common airflow restrictions include:

- Clogged cabin air filter

- Weak blower motor

- Blocked evaporator core

- Debris inside the HVAC housing

Airflow problems raise low side pressure without raising high side pressure significantly.

Expansion Valve Or Orifice Tube Issues

The expansion device controls how much refrigerant enters the evaporator.

If it fails to restrict flow properly:

- Too much refrigerant enters the evaporator

- Pressure does not drop enough

- Low side readings climb

A stuck-open expansion valve or damaged orifice tube often causes high low side pressure with mediocre cooling.

This failure is easy to misdiagnose as overcharge.

Compressor Not Creating Enough Pressure Difference

The compressor must create a clear pressure split between high and low sides.

If the compressor is weak:

- Suction pressure stays high

- Discharge pressure stays low

- Cooling becomes poor

Internal wear, damaged valves, or clutch slippage reduce compression efficiency.

In these cases, the system looks pressurized but lacks temperature drop.

AC Compressor Clutch And Control Problems

A compressor that cycles incorrectly can raise low side pressure.

If the clutch stays engaged too long or disengages at the wrong time:

- Pressure equalizes too quickly

- Low side pressure remains elevated

- Cooling becomes inconsistent

Electrical control issues, pressure switch faults, or control module errors often contribute.

Condenser Airflow Problems Affecting Low Side Pressure

The condenser releases heat from the refrigerant.

When condenser airflow is poor:

- High side pressure rises

- Refrigerant does not condense efficiently

- Expansion becomes less effective

- Low side pressure increases

Blocked condenser fins, inoperative cooling fans, or debris buildup can create this condition.

Although the issue begins on the high side, the low side reacts as well.

Moisture Or Air Inside The AC System

Air and moisture do not compress or expand like refrigerant.

When trapped inside the system:

- Pressure readings become inaccurate

- Expansion behavior becomes erratic

- Cooling efficiency drops

Moisture can freeze inside the expansion device, causing unstable pressure swings.

Proper evacuation removes air and moisture before charging.

Incorrect Refrigerant Type Or Oil Amount

Using the wrong refrigerant or incorrect oil volume affects pressure behavior.

Different refrigerants operate at different pressure ranges.

Too much oil reduces heat transfer and displaces refrigerant volume.

Both issues can cause elevated low side pressure with poor cooling.

Always match refrigerant and oil type to manufacturer specifications.

How Ambient Temperature Affects Pressure Readings

Outside temperature strongly influences pressure readings.

High ambient heat raises baseline pressures.

However, even in hot conditions, low side pressure should drop once the system stabilizes.

Consistently high readings regardless of cooling demand point to mechanical or airflow problems rather than temperature alone.

Interpreting Gauge Readings Correctly

Gauge readings should always be interpreted together.

High low side pressure with:

- Normal high side pressure suggests airflow or expansion issues

- High high side pressure suggests overcharge or condenser airflow problems

- Low high side pressure suggests compressor inefficiency

Reading one gauge alone leads to wrong conclusions.

Why Vent Temperature Matters More Than Pressure Alone

Pressure readings only tell part of the story.

Vent temperature shows real-world performance.

If low side pressure is high and vent temperature is warm, refrigerant is not absorbing heat effectively.

Cold vent air with high low side pressure is rare and usually temporary.

Temperature confirms whether pressure readings reflect a real problem.

Common Misdiagnoses With High Low Side Pressure

Many systems with high low side pressure are misdiagnosed as low refrigerant.

Others are misdiagnosed as compressor failure when airflow is the real issue.

Replacing parts without confirming airflow, charge weight, and control behavior often leads to repeat repairs.

Accurate diagnosis prevents unnecessary expense.

Step-By-Step Logical Diagnosis Approach

A proper approach includes:

- Confirming refrigerant charge by weight

- Inspecting cabin and condenser airflow

- Observing compressor cycling behavior

- Comparing vent temperature to pressure readings

- Checking expansion device function

Skipping steps creates confusion rather than clarity.

Why DIY Recharge Kits Create Pressure Problems

Recharge kits rely on low side pressure only.

They do not show high side pressure, refrigerant weight, or system condition.

Users often add refrigerant until pressure “looks right,” which causes overcharge.

This is one of the most common reasons systems show high low side pressure.

How Electronic Controls Influence Pressure

Modern vehicles use sensors and control modules to regulate AC operation.

Faulty signals can:

- Prevent compressor modulation

- Delay clutch cycling

- Keep pressures elevated

Sensor data errors may not trigger warning lights immediately.

Scanning live AC data helps confirm electronic control behavior.

When High Low Side Pressure Appears Intermittently

Some systems show normal pressure at idle but high pressure while driving, or vice versa.

This often points to:

- Fan control issues

- Variable displacement compressor faults

- Heat-related expansion valve behavior

Intermittent behavior requires testing under real operating conditions.

Risks Of Ignoring High Low Side Pressure

Ignoring pressure imbalance leads to:

- Reduced cooling comfort

- Increased compressor wear

- Higher fuel consumption

- Premature component failure

Operating outside design pressure ranges shortens system life.

Can High Low Side Pressure Damage The Compressor

Yes, especially over time.

Excessive suction pressure increases internal temperature and stress.

Oil circulation may become uneven.

While immediate failure is uncommon, long-term damage is likely.

Temporary Improvements That Do Not Fix The Problem

Cooling may briefly improve after:

- Adding refrigerant

- Letting the system rest

- Driving at highway speed

These changes do not address the underlying cause.

Temporary improvement often delays proper repair.

Why Full System Service Is Sometimes Necessary

In systems with unknown service history:

- Refrigerant type may be incorrect

- Oil amount may be wrong

- Moisture may be present

A full evacuation, inspection, and recharge restores baseline operation.

This provides a clean starting point for diagnosis.

Cost Perspective On Correct Repairs

Many causes of high low side pressure are inexpensive to fix.

Airflow problems, filters, and fans cost far less than compressors.

Accurate diagnosis avoids replacing major components unnecessarily.

The cost of proper testing is usually lower than repeated repairs.

Preventing Pressure Imbalance In The Future

Preventive steps include:

- Avoiding DIY recharge shortcuts

- Maintaining cabin and condenser airflow

- Addressing cooling fan issues early

- Servicing the system correctly when opened

AC systems reward careful service and punish guesswork.

Why Pressure Alone Never Tells The Whole Story

Pressure reflects conditions, not causes.

Two systems can show the same pressure with entirely different faults.

Combining pressure, temperature, airflow, and behavior provides accurate answers.

This approach separates professional diagnosis from trial-and-error repair.

Final Thoughts

High low side AC pressure is not a mystery once the system is viewed as a balance of airflow, refrigerant flow, and mechanical control. It usually means refrigerant is not expanding and absorbing heat the way it should. Overcharging, airflow restriction, expansion device faults, compressor inefficiency, and control issues all lead to the same pressure symptom while requiring very different solutions.

Treating the gauge reading as a starting point rather than a diagnosis prevents costly mistakes. When pressures, temperatures, and airflow are evaluated together, the real problem becomes clear. Fixing the cause instead of chasing the number restores cooling performance and protects the AC system from long-term damage.